The principles of R290 system design

At Clade, we’ve always been at the front of the curve when it comes to manufacturing, designing and installing R290 (propane) heat pump systems.

Just a year ago, we were one of the only suppliers of R290 heat pumps. But now, there are many suppliers available – and for good reason!

R290 refrigerant gas is incredibly high-performing and has excellent environmental credentials with an incredibly low global warming potential (GWP).

With that in mind, I thought it time to share the principles of R290 system design, and to take a look at some of the key considerations that need to be accounted for when working with this refrigerant.

Here’s all you need to know.

What are the principles of R290 schematic design?

The principles of R290 schematic design are very similar to those of CO2 schematic design, which I’ve written about previously.

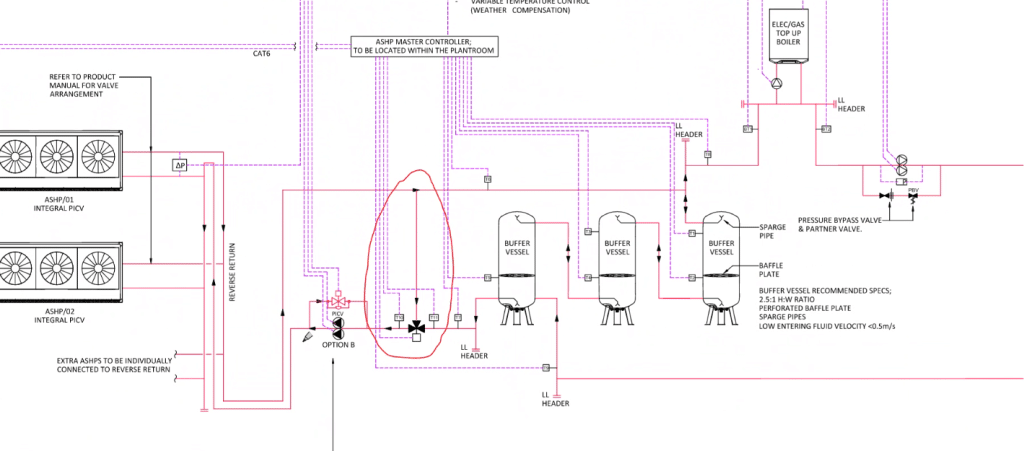

A schematic is essentially a full drawing of how all the pipework in a building connects, showing the entire building on one piece of paper.

This includes all emitters, heat pump units, buffer vessels, valves, and more.

Just like CO2 systems, a Clade R290 system will usually require…

- A buffer vessel to provide the hydraulic separation between the primary side and secondary side, so that both can do their jobs without interfering with one another

- Two domestic hot water (DHW) cylinders for DHW production – a hot store vessel and a stratification cylinder

- A building management system (BMS) that can alert building operators to high or low return temperatures, so any issues can be resolved before they cause the heat pump to turn off

- Proper controls to maintain the Delta T (the difference between the flow and return temperatures)

There’s only one visible difference between a Clade CO2 schematic and a Clade R290 schematic: a Clade R290 system requires three-port back-end protection valves.

R290 and three-port back-end protection valves

When we’re designing an R290 system – or looking at a third-party design for a Clade R290 heat pump – we look for a three-port back-end protection valve.

That’s the section circled in red on this example R290 schematic.

Why do we need three-port back-end protection valves?

Three-port back-end protection valves are important on our R290 systems because R290 has a much smaller Delta T than CO2.

With CO2, we design for a 30C return temperature. But with R290, we design for a 60C flow and a 50C return (although our high-temperature Elm and Yew heat pumps are slightly different).

This gives us a 10C Delta T, which makes for conditions much more similar to those used by traditional gas boilers.

The benefit is that it makes retrofitting R290 particularly straightforward. But it also means the need for bigger pipework and, of course, three-port back-end protection valves!

It’s worth noting that a three-port back-end protection valve isn’t always necessary, as it will also depend on peak load and kilowatt delivery.

However, if you’ve got a kilowatt imbalance (for instance, you’re using buffer vessels as a load) then a three-port back-end protection valve is a must.

What does a three-port back-end protection valve do?

The job of the three-port back-end protection valve is to work continuously to maintain the desired return temperature to the heat pump.

Clade commercial heat pumps work based on a controls philosophy that requires a consistent Delta T.

So, let’s imagine for a minute that your return temperature drops to 45C from the desired 50C.

This would ordinarily cause your flow temperature to drop too – so, you’d end up with a 55C flow temperature instead of 60C. Not ideal!

That’s where your three-port back-end protection valve comes in.

This valve will maintain your heat pump return temperature so that it’s always 10C below your desired flow temperature – therefore maintaining the flow temperature.

It does this by mixing some of the warmer flow with the cooler return, to get to that desired return temperature and keep that Delta T exactly where it should be.

The principles of DHW production on an R290 system

If you’re hoping to produce both space heating and DHW with your air source heat pump, there is another key difference between CO2 and R290 systems.

Essentially, with CO2, you can easily produce DHW at 60C through a plate exchanger.

This is because CO2 typically operates at high temperatures.

On the other hand, most R290 systems (discounting our high-temperature Elm and Yew units) will struggle to produce a guaranteed 60C hot water supply without a bit of help.

This is because the maximum flow temperature they can generally reach is 65C, and then you’ll typically experience losses getting to the plate and crossing it – meaning you could easily end up with a 59C DHW supply instead of 60C.

Yes, it’s very close. But it’s not compliant.

That’s why, when it comes to R290 systems, we typically use an electric boiler to top up the temperature of DHW after it’s heated up by the plate exchanger.

So, if we’re left with a 59C supply of hot water after crossing the plate exchanger, the electric boiler will top the temperature up to 60C to make sure it’s compliant.

This way, you get a guaranteed, compliant DHW supply while keeping just one system for space heating and DHW.

It does involve paying to run an electric boiler. But because the heat pump is doing the majority of the work, this is still much more efficient – and cost-effective – than running a gas boiler.

It’s also ideal for retrofit projects, as you’ll be able to benefit from the fact that R290 requires fewer secondary side changes while still enjoying an efficient (and low carbon) DHW supply. Which brings us onto…

Minimising secondary side changes

The great thing about an R290 system is that the Delta T closely matches the Delta T of a traditional boiler.

This means you can often get away with making fewer changes to the secondary side – which tends to be a priority for retrofit clients.

After all, it keeps costs down, minimises disruption, and allows for continuous operation.

Often with an R290 system, you’ll be able to retain pipework, valves and more – simply switching out the emitters for larger ones (although if a building’s emitters were previously oversized, sometimes even this won’t be necessary).

In fact, our high-temperature Elm and Yew R290 heat pumps can work as direct boiler replacements, and are designed especially for buildings where changes can’t easily be made to a building’s infrastructure – like listed buildings and hospitals.

In this way, when it comes to retrofitting a heat pump, there’s less design velocity that has to go into an R290 system compared to a CO2 system.

Weather compensation

Another benefit of R290 is the ability to weather compensate.

This can drastically improve your heat pump’s efficiency and therefore lower your heating bills even more.

Essentially, when it comes to R290, Delta T is the priority – in contrast to CO2, which is dependent on maintaining a set return temperature.

This means that, when ambient temperatures are -5C, you could have a flow and return of 80-70.

Meanwhile, if ambient temperatures climb to 5C, you could adjust the flow and return to 50-40 to drastically improve your heat pump’s COP.

Better still, many buildings already have weather compensation built in, so tagging propane onto these existing systems is generally quite easy– another reason why R290 is easier to retrofit!

Safety considerations for R290

Unlike CO2, R290 is flammable.

This means there are some key safety requirements that we have to establish as a manufacturer – although the regulations around it are still quite vague.

Our blog on R290 and flammability goes into a lot more detail. But here are some key safety measures we prioritise here at Clade.

Degasser

A degasser isn’t a legal requirement. But at Clade, we like to be standard setters in the industry and always recommend a degasser for our R290 heat pump systems.

This safety device would mitigate any damage to your system and ensure the safety of everyone inside the building in the very unlikely event that your plate heat exchanger fails and allows propane to leak into the heating system itself.

Safety valves

Like all heat pump systems, R290 systems require safety valves.

If there’s a fault and temperatures start rising, these release pressure in the system so that the pipework doesn’t burst.

ATEX zone

All R290 heat pump units have an ATEX zone, which is basically an area above the heat pump where you can’t put anything that might catch fire.

This is in case there’s a pressure fault in the system that causes the safety valve to expel any pressure and gas.

Location

At Clade, we also advise designers to be mindful of what’s around the unit, even when it’s not in operation. After all, there’s always a chance that there’s a fault that causes propane to leak to the side of the unit when it isn’t running.

That’s why we suggest designers always do a DSEAR assessment (a kind of on-site safety assessment) to ensure R290 units are being positioned somewhere suitable, away from potential sources of ignition.

Talk to us about R290 systems

As you can see, there are lots of things to take into account when designing an R290 heat pump system.

But they also require a lot less work than CO2 heat pumps when it comes to retrofit projects. Plus, when you get the design right, the rewards are many.

Building owners can benefit from an efficient, low-carbon and safe heating system that’s easy to retrofit and even allows for weather compensation.

At Clade, we’ve been at the front of the curve when it comes to manufacturing, designing and installing R290 heat pump systems for years. So, you’re in safe hands!

Simply get in touch to find out more and get your project started.