Beyond Installation: How Clade Delivers Heat Pump Aftercare That Lasts

When a commercial heat pump is first installed and commissioned, it’s working at peak efficiency: delivering the performance and carbon savings promised in the design phase. But maintaining that level of performance year after year doesn’t happen by accident.

Heat pumps are long-term assets that depend on active care, data-driven maintenance, and technical expertise. Without that, even the best-engineered systems lose efficiency, reliability, and ultimately value.

At Clade, aftercare isn’t an afterthought. It’s a core part of how we deliver trusted, long-lasting systems.

Proactive Maintenance Scheduling

Preventative care starts with structured, proactive maintenance.

Rather than waiting for something to go wrong, our Aftercare Team builds maintenance schedules around operating data, manufacturer guidance, and the real-world conditions of each site.

Service intervals are carefully planned to ensure systems are reviewed before issues arise. Engineers monitor logs, operational hours, and temperature profiles to identify early signs of inefficiency or imbalance.

That foresight means issues are identified long before they affect heating performance or energy use, often before the client even knows there’s a problem.

For example, during remote checks, our engineers recently detected an anomaly in a system’s fluid flow at a site in Scotland. Within an hour, our remote and software teams collaborated, adjusted the control strategy, and restored full operation, and all without anyone needing to travel to the site.

This kind of proactive, data-led intervention is something no other UK heat pump manufacturer currently provides.

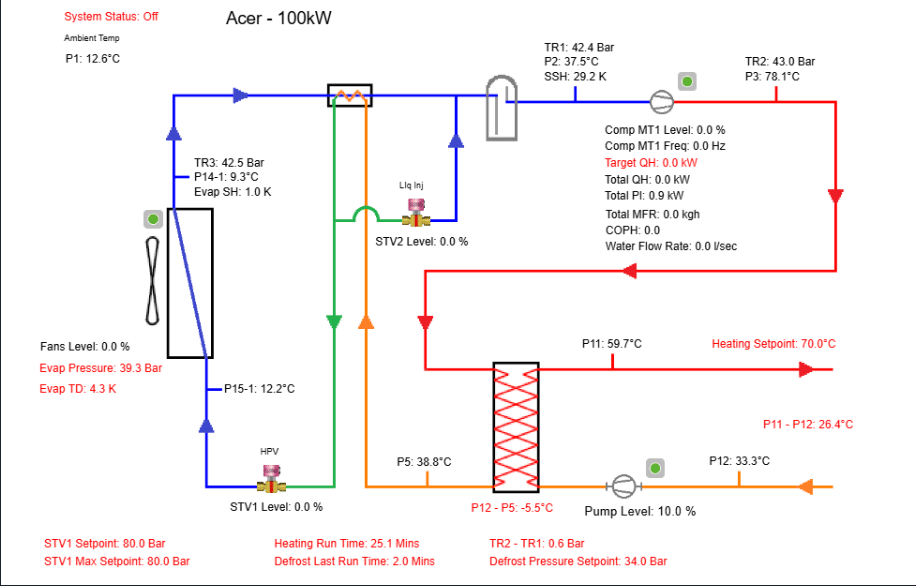

Our engineers remotely monitor every Gold-package system at least every 24 hours, analysing live data from hundreds of heat pumps nationwide (and even some abroad) to spot irregularities in temperature, pressure, or performance. It’s a level of real-time insight that allows Clade to prevent downtime altogether.

Routine System Checks that Safeguard Efficiency

Every maintenance visit follows a consistent process designed to safeguard efficiency and extend system life.

Core checks include:

- Refrigerant pressure and charge verification, ensuring the system operates within design limits.

- Inspection and cleaning of airflow paths, as blocked coils or restricted airflow can cause significant energy losses.

- Electrical and mechanical integrity checks, identifying wear before it becomes a failure.

- Control and Building Management System review, confirming that setpoints, pump speeds, and communication parameters are optimised for the building’s current usage.

Even small deviations in temperature differential, flow rate, or control strategy can reduce performance. That’s why each visit is logged and compared to historical data, as it creates a detailed record of system behaviour over time.

Long-Term Performance Optimisation

Maintenance is more than just preventing breakdowns; it’s about preserving design intent.

Buildings evolve, and occupancy levels, heating demand, and control strategies change. Without active optimisation, performance drifts.

Clade’s aftercare approach focuses on maintaining real-world efficiency through continuous monitoring and system tuning. Engineers analyse data from operation logs and site telemetry to identify trends such as excessive compressor cycling or inconsistent return temperatures.

Adjustments might include:

- Rebalancing hydraulic systems

- Fine-tuning buffer tank control

- Adjusting temperature curves for seasonal conditions

- Refining BMS logic for part-load operation

These refinements ensure the system continues to perform as efficiently as the day it was commissioned or better.

Why Professional Servicing Matters

Heat pumps are not boilers. Their operation is significantly more sensitive to pressure, flow, and control conditions, and they require specialist understanding to be properly maintained.

General HVAC maintenance teams may not have the experience or access to the manufacturer-specific data needed to diagnose complex issues, which is why professional servicing makes such a difference.

Clade’s Aftercare Engineers are trained specifically on our product range: from CO₂ Maple and Acer systems to R290 Birch and Elm models. They understand how each unit behaves in practice as well as theory.

Our team also has direct access to the engineering and design teams that built the systems, meaning insight and support are always only one call away.

For our clients, that means faster fault resolution, accurate diagnostics, and greater peace of mind, all backed by a UK-based spares network for minimal downtime.

Flexible Aftercare Packages: Gold, Silver and Bronze

Every site is different, and so are its maintenance needs. That’s why Clade offers three tiers of Aftercare Service Cover, designed to give clients the right balance of protection, performance, and cost-efficiency.

Gold – Fully Comprehensive Service

Our Gold package provides complete peace of mind. It includes major and minor planned preventative maintenance (PPM), bi-monthly evaporator cleaning, remote fault monitoring, seasonal adjustments, and all labour and materials (outside of warranty spares).

Gold-level clients enjoy a fully inclusive service, meaning both time and materials are covered for any repairs or replacements needed during the contract period.

Ideal for mission-critical environments such as hospitals, universities, and commercial developments that cannot afford downtime.

Silver – Balanced Protection

The Silver package offers the same high-quality care (major and minor PPM, remote monitoring, and seasonal recommissioning), but reactive repairs are billed separately (except for parts covered under warranty).

It’s the perfect option for clients with internal maintenance support who still want expert oversight and periodic system optimisation from Clade.

Bronze – Essential Care

The Bronze package provides the essential level of support (major annual PPM and remote fault monitoring), ensuring systems remain compliant, efficient, and operational.

It’s a cost-effective option for sites that are less sensitive to downtime but still require expert oversight to maintain performance and safety.

Reactive Support and Remote Monitoring

When issues do arise, Clade’s reactive service network ensures rapid response. All service calls are logged and handled directly by a member of the Aftercare Team.

Our remote monitoring platform allows engineers to assess live system data before attending the site, ensuring the right resources are dispatched immediately.

For Gold-tier clients, callouts and repairs are included. For Silver and Bronze tiers, estimated repair costs are agreed upon before any work proceeds.

This transparency and responsiveness are what keep our clients confident that their systems are in safe hands.

Data-Driven Insight

Data is central to modern aftercare. Every Clade system provides a stream of operational data that helps us monitor performance and spot anomalies before they become problems.

By tracking parameters such as Coefficient of Performance (COP), flow and return temperatures, and compressor run times, our team can see how systems evolve in the field.

When trends suggest potential issues, like a gradual efficiency drop or excessive cycling, we act early.

This data-driven loop also feeds back into our R&D and design teams, which helps us continuously refine our products and improve performance across future installations.

It’s an integrated approach, as every system we maintain helps us make the next one better.

Talk To Us About Aftercare

From proactive monitoring and system optimisation to professional servicing and spare parts availability, every stage plays a vital role in keeping your system efficient, reliable, and futureproof.

But it’s not something you need to worry about.

You can leave that to our experienced team of engineers here at Clade, who will support you from design and installation all the way through to commissioning, servicing, and performance optimisation.

With over 35 years of experience working with natural refrigerant heat pumps and refrigeration systems, we understand exactly what it takes to keep systems running at their best for the long term.

Just get in touch to learn more or start planning your aftercare package today.